Supporting trailer-makers with a re-engineered brake calculation process

Whether they are making a one-off product or a series production run of thousands, trailer-makers are required by law to carry out a brake calculation before build.

This calculation ensures that the braking components specified will be sufficiently sized and well-integrated to produce enough stopping power to meet the statutory requirements; in this case, UNECE Regulation 13. It is an essential part of the vehicle’s homologation paperwork.

Normally, the way that the brake calculation process works is that trailer builders submit technical information about the trailer, and the brake OEM carries out the calculations based on those figures.

At Haldex, that workflow will continue, but better, thanks to a new brake calculation tool developed in-house. The new app streamlines the process, making it easier to input information, quicker to produce a report, and offers new features – including the possibility to entrust certain customers to use the tool to produce their own calculations.

Now, the request form, which had been essentially a digitised paper document, has been turned into a web form that is easier to fill in, and more consistent. This helps reduce the need for the team to check users’ facts, which can cause delays.

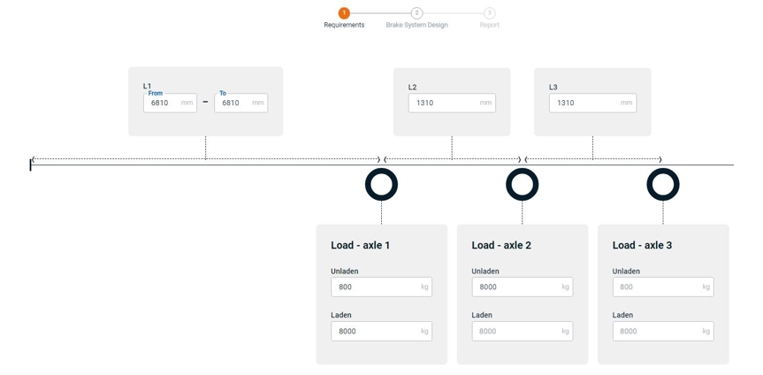

The new web form is clear and simple to use. Technicians fill in vehicle, project and trailer information: the type, number of axles, tyre sizes, braking system, dimensions, centre of gravity, and typical loads. The trailer hardware section covers suspension and brake system components. Users select options from drop-down menus, based on options stored in a database.

The new version of the form is now available on the Haldex website for semi-trailers. Web forms for drawbar (or full trailers) and centre-axle trailers are expected to go live by end of Q2 2024.

In most cases, once the form has been completed, it is sent on to the Haldex team for processing. But one of the great benefits of the system is that it can also be opened up for use by external experts, for the first time.

Qualified users – and Haldex grants access to that system on a case-by-case basis – can access the brake system design screen, which generates performance parameters based on the supplied data. It also automatically compares those performance parameters to the regulatory limits. That comparison appears as a highlight colour behind the figures: green means that the set-up is within the legal requirements, red that it does not.

Users can adjust the results by changing the equipment specification; the system updates in real-time. Users are free to modify the system within the regulatory limits, and even outside of them. However, if the boxes are not all green, the tool will not allow the user to progress to the next step. Nor are even authorised users allowed to adjust the system’s pre-set limits.

Once the calculation is completed (within regulatory requirements), the tool automatically produces a report, which includes technical documentation including a copy of the braking schematic.

A further development due next year will see the system auto-tune performance parameters to comply with regulatory requirements (every box goes green). In that scenario, users would still have the ability to modify the specification as before to achieve an optimal setup.

Explaining the philosophy behind the new brake calculator, Kristoffer Örndahl, mechatronics design chief engineer, who headed up the development team, says: “The expertise is now more in the tool than in the people using the tool. The idea is that the people doing the brake calculations is moving from only Haldex personnel to external companies like manufacturers, compared to in the past. The idea is to go further with that, so more and more customers can do it for themselves.”

The new tool originated in retirement and corporate shifts. For 20 years or more, a specialist Haldex team based in Heidelberg, Germany used software that they had developed in-house to perform the 2,000 brake calculation requests that the company receives per year. Things began to change a few years ago, when some of that team began to retire. When the Heidelberg factory was shut down in 2020, brake calculations were transferred to Haldex headquarters in Landskrona, Sweden, a site that primarily focuses on product research and development. During that process, external consultants helped the company capture their specific knowledge.

Örndahl adds: “The idea was born in the group to make a new tool to save our time as we do it, and to make it easier for customers to fill in information. That will mean a quicker turnaround.”

A Haldex team worked with a local software developer for more than a year on the project, recalls Örndahl. “I would say it was like learning to ride a bicycle again. We started from the beginning, and went through the R13 regulation, which is a big document, and the legal requirements. Slowly, day by day, together with the development company and experts at Haldex, we built up the calculations from the beginning.”

He adds that the team was always aware of the safety importance of the project since any incorrect results could affect road safety. “Along the way we did validation of the new calculations; we always performed them using old and new methods, and looked at the results, and checked that they were the same and within the R13 regulation.”

In the event, few of the core algorithms were changed. Process improvements were limited to identifying a few misunderstandings and clarifying a few calculations (not related to the regulations). What did change, Örndahl added, was how the system handles data, which was completely modernised.

The result is a sleek and modern interface, fully validated, that performs a task which is vital for the safety of trailers and the road users around them. The project is a great example of how Haldex continues to invest in its systems and processes for the benefit of customers now and in the years to come.