Air disc brakes

ModulT offers cost-effective combination of durability

and optimised weight reduction

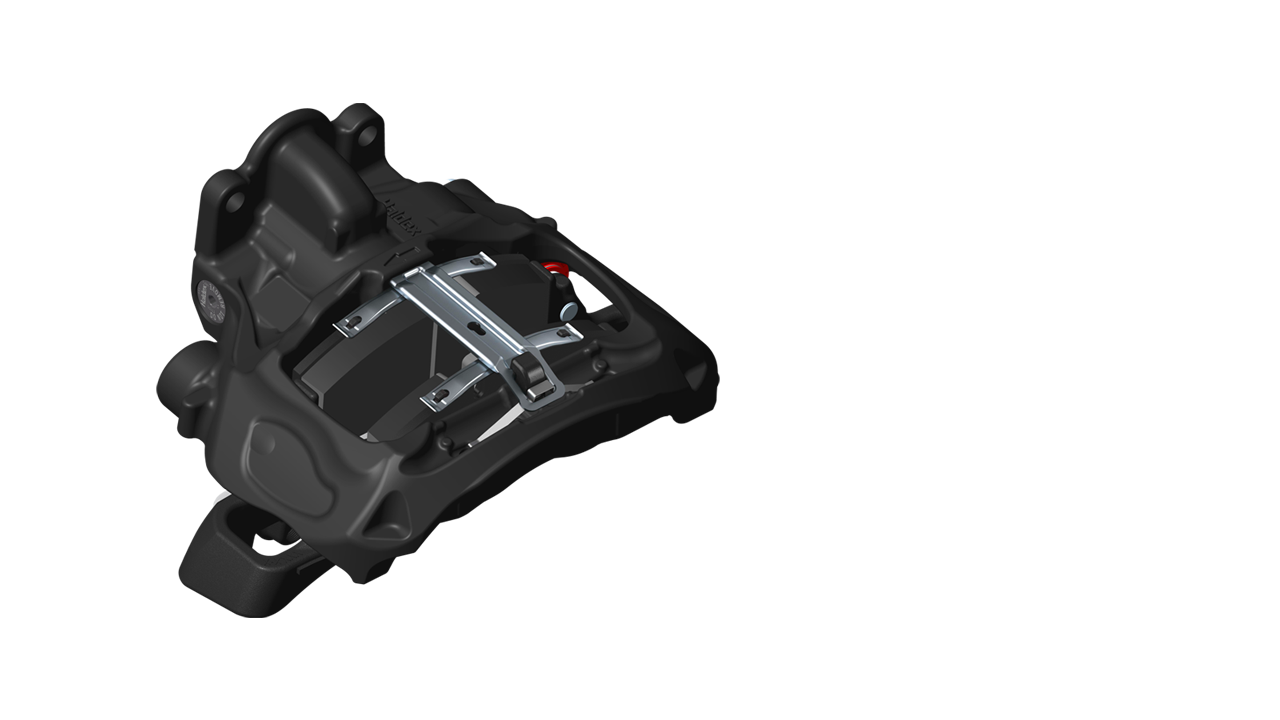

The Haldex ModulT program is an innovative air disc brake platform developed specifically for the purpose of meeting increased customer demands on performance, robustness, service up-time, weight and total cost. The basic design of the ModulT consists of a large single tappet mechanism, a monobloc calliper and two sliding pins.

The key factor of the ModulT product line as a whole is light weight and optimised design. The design of the ModulT caliper body, a metal casting, went through a computer-based topology optimisation tool that involves only having material where it is absolutely required when making a strength calculation. By placing forces on the model and observing its reaction, the program calculates how much material it needs to keep. Product designers use this information to fine-tune the model for production.

Other design features support the slimmed-down form. The single casting reduces weight by avoiding the need for an extra interface for bolting together (as well as the bolts). A stainless steel sliding pin offers long lifetime and even pad wear. A single, rather than twin, tappet mechanism involves fewer parts. This single tappet brake includes a relatively wide T-shaped thrust plate, similar to a two-tappet design, ensuring an even pressure application to the brake pad.

Including pads, the DBT22LT caliper for 22-inch wheels weighs just over 30kg (depending on the carrier) and creates 20kNm braking force, while the smaller DBT19LT is 29kg, including pads, and generates up to 18kNm braking force. The benefits don’t end with small size. A modular approach to design means that both brakes use exactly the same components except the pads, caliper and the carrier. The benefit for the customer is the same spare parts for both brakes. That reduces the complexity of ordering and parts stocking.

Key benefits

- Low weight

- Single tappet mechanism with similar clamping force distribution as Haldex twin tappet mechanism

- Simplified maintenance; boltless pad retainer and only two bolts in the complete brake

- Modular; the same mechanism and sliding function design used on multiple brake sizes

- Long service life; stainless sliding pins, PTFE coated steel bushings, and the mechanism bellows is folded inwards thus protected from external affection (stones/blister etc.)

- High efficiency; the use of double roller bearings for the mechanism lever keeps the hysteresis low and thus a high efficiency is achieved

What sets us apart

The ModulT is designed to provide high performance coupled with low weight, durability and a minimum number of wearing parts. The ModulT enhances a floating monobloc calliper and an integrated adjustment unit which compensates for brake pad wear. The unit, which is actuated by the mechanism lever, presses the inner brake pad against the disc, which then causes the calliper to slide laterally so that the outer brake pad also comes in contact with the disc. The calliper moves on slide pins. Where the disc brake also serves as a parking brake, the unit is actuated by a spring brake chamber.

High stability, light weight and extremely simple service are the factors that are behind the success of the disc brake family ModulT.

› Designed for 17.5-, 19.5- and 22.5- inch wheels

› Applications for Truck, Bus and Trailer

ModulT GenI

The ModulT disc brake creates added value through its reduced weight without brake functionality or stability reduction.It meets customer demand for the lowest possible weight and can be used universally on both semi-trailers and drawbar trailers with axle loads of up to nine metric tonnes. GenI is in serial OE supply now replaced by GenII.

ModulT GenII

Since 2018 we have supplied the updated version of the ModulT DBT22LT named GenII. This version is a more optimised version of the GenI, focused on significantly reducing weight. The DBT22LT GenII looks slightly different than GenI, however, the operational performance is equal.

Trailer Application Guide - Air disc brakes

Whether vehicle construction, workshop repair or spare part distribution, the Trailer Application Guide provides unique electronic access to all Haldex systems for trailers.

Lightweight brakes with heavyweight performance

Product catalogue

Quick and easy access to the full range of Haldex products. Each part number shows the product’s technical specification, price and picture.

Technical Documentation

Our extensive database of technical documentation contains all relevant information on our products.