Installation

The pressure protection valve is normally installed directly into the vehicle reservoir using an M22 bulkhead connector (vehicle piping diagram required before installation). The air flow direction from 1 to 2 (see arrow on valve) must be observed.

Port 1 IN from reservoir

Port 2 OUT to auxiliary

Testing

- Check for correct function and air leaks

- Check opening and closing pressures with test gauges. In the port 1 and/or 2 the pressures must be in according to the index versions and data of the vehicle manufacturer

- Leak-tightness check

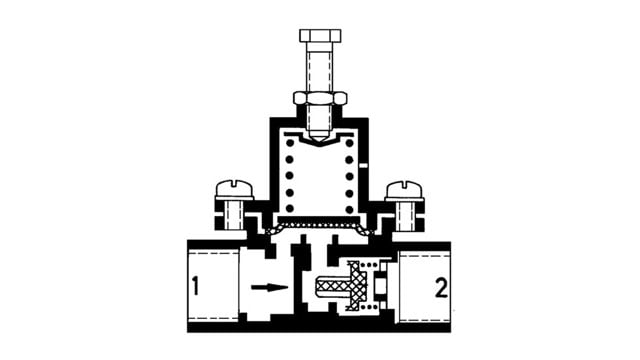

Charge position

Air flows through port 1 and pressurizes the underside of the diaphragm. After reaching the adjusted opening pressure, the diaphragm moves off its seat and air flows through port 2 and thus to the auxiliary circuit. On the valve without back flow in addition the before port 2 located check valve is opened.

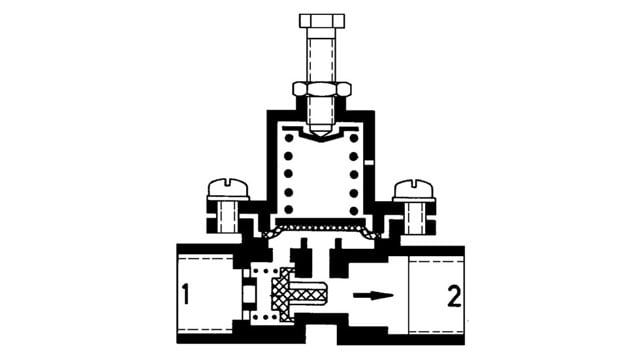

Protect position

At a relatively large drop in pressure at port 2, e.g. a defect in the auxiliary circuit, air from port 1 flows into port 2, until the spring presses the diaphragm onto its sealing seat. In port 1 the protected pressure remains.

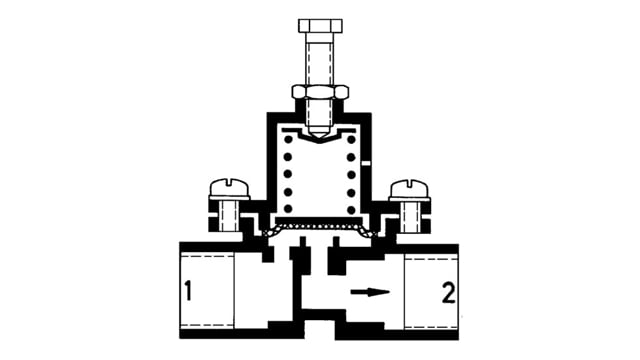

Back flow position

In the back flow position in port 2, the pressure indicated in the index remains.

1. Valve without back flow C :A drop in pressure at port 1 the check valve closes, resulting in no back flow from 2 to 1.

2. Valve with back flow A : A drop in pressure at port 1 the check valve opens, whereby air from port 2 can flow to port 1.

3. Valve with limited back flow B : A drop in pressure at port 1, air flows from 2 to 1, until the power of the spring overcomes the pressure beneath the diaphragm, sealing the protected pressure in port 2. If a defect occurs in port 2 (ventilation to 0 bar) protected pressure must remain in port 1 (on all versions).

Valve without back flow C: 314 012 ...

Valve with back flow A: 314 013

Valve with limited back flow B: 314 014 ...