Installation

The lift axle raises or lowers automatically when the change-over pressure is reached or when the voltage is switched ON or OFF, respectively. Keep away from the hazardous area!

Mechanical Installation

The ILAS-E should be mounted using the holes which are provided. It should not be located in an area where there is excessive water spray/splash and should be protected from high-pressure washing equipment. Additional protection should be provided by the vehicle manufacturer against unintentional activation.

In the event of paint/coating work, all open connections including the exhaust port should be protected by suitable means to avoid penetration of the paint/coating. After painting/coating remove this protecting material. In the supply coming from the air reservoir, a line filter should be installed (to guard against pollutants).

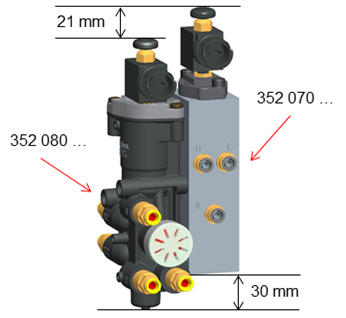

Comparison

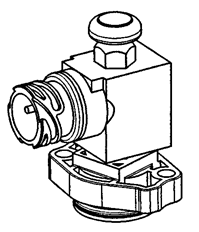

The total size between the current series 352 070 … and the new generation 352 080 … deviates slightly as shown below.

Pneumatic Installation

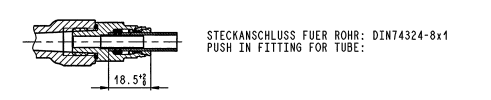

Pneumatic connection should be following assembly diagrams. The exhaust port „3“ should be protected against contamination. When assembling pneumatic lines care should be taken to ensure that the tubes are cut square and free from burrs. On valves with push-in fittings use only nylon pipes (depends on version) 8x1 in accordance with DIN 74 324. When assembling the nylon pipes, care should be taken to ensure that the pipes are cut square, to the required length and are free from burrs. Before inserting the pipes in the push-in fittings don´t support sleeves in the ends of the pipes because the sleeves are integrated inside of the brass fittings. Pipes are to be inserted at least 18.5 mm deep in the connections.

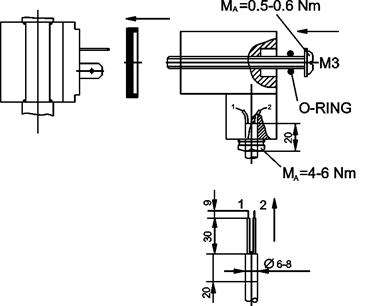

Solenoid socket

Strip the insulation off the PUR cable as per the diagram. After wiring tighten the PUR cable with the PG- screw (4-6 Nm). Fix the sealed connector cover with the screw (M3) (0.5-0.6 Nm) and seal up the screw with the O-ring ø 3 x 1.5 (within the assembling kit) . Cable should run up to connector-cover.

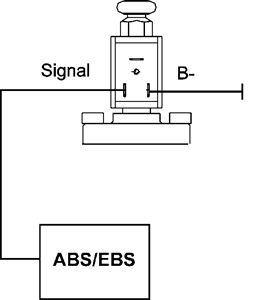

Solenoid bayonet

Use bayonet according to DIN 72585. On bayonet the union nut must be attached suitable and engaged correctly by turning clockwise to guarantee optimal sealing. For Haldex EB+ you can use cable with part-no. 814 012 xxx

Inspection

- Test for operation and leaks.

- Test for correct assembly

- Check the instruction label

Maintenance

To lower the lift axle, e.g. for servicing the electric power must be switched off. Alternatively a shut off cock with exhaust (e.g. 334 077 001) can be fitted to port 1 to switch off the lifting device (axle down). If defects are noted during vehicle examinations or when driving, then the unit should be tested and replaced if necessary.

When working with high pressure cleaners a distance of at least 50 cm should be observed.